Universal Clamps for Pile Driving Systems

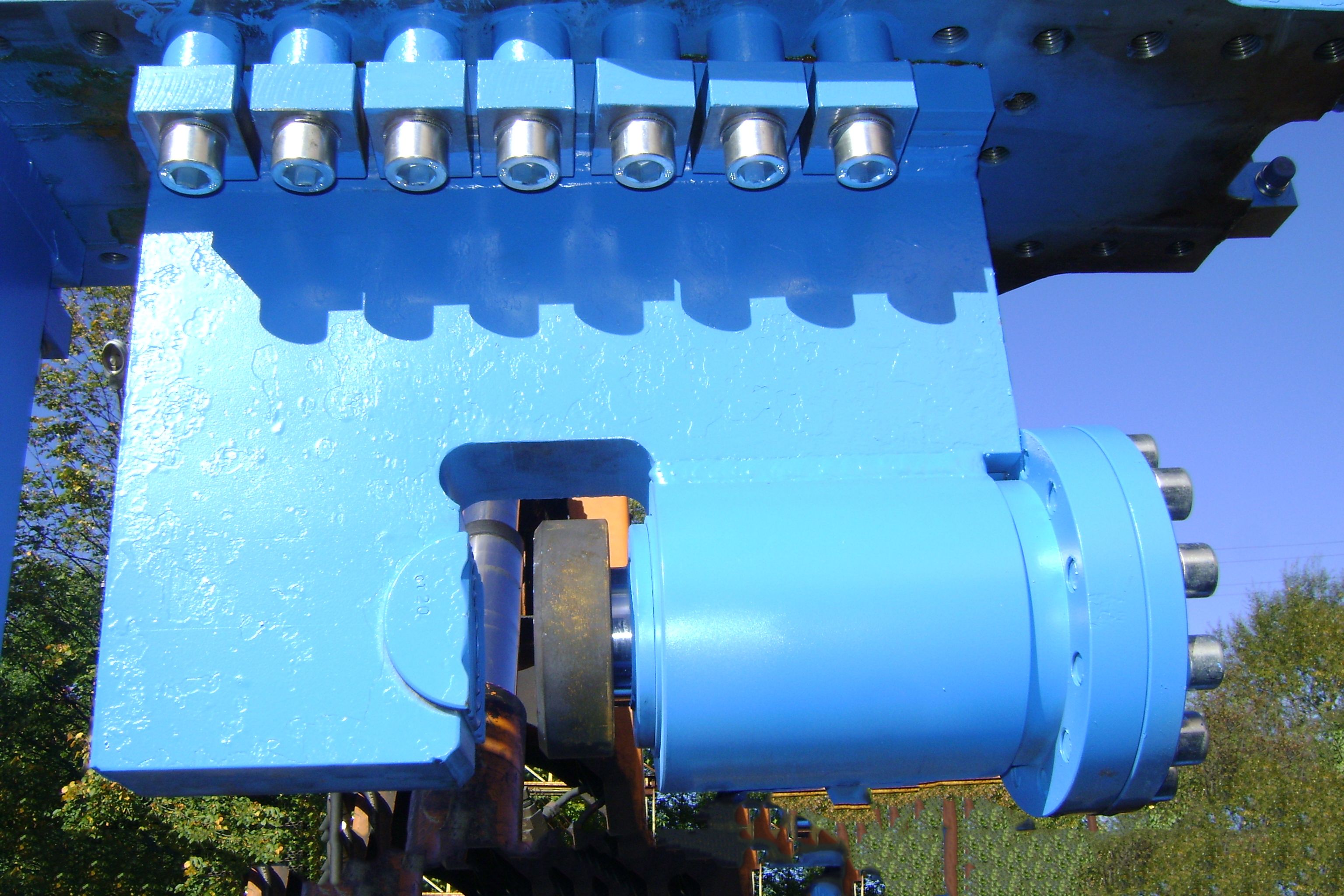

Versatile. Secure. Built for Any Pile Type.Universal clamps are the critical connection point between your pile driver and the pile. They ensure a safe, stable grip during operation — reducing slippage, improving alignment, and enabling consistent driving force across a wide variety of pile shapes and soil conditions.

At Pile Driving USA, our universal clamp systems are engineered for job site versatility. With interchangeable jaw inserts and a durable steel body, they handle everything from sheet piles and round pipes to H-beams and custom profiles — without needing to switch clamp assemblies between tasks.

- Compatible with all Pile Driving USA vibratory hammers

- Adjustable jaw sets for multi-profile flexibility

- Fast jaw changes on-site with minimal tools required

Why Are Universal Clamps and Why Are They Essential?

Universal clamps secure the pile within the hammer assembly, allowing the driver to transfer energy directly into the pile without slippage or damage. This secure interface is especially important under heavy vibration, variable soil loads, and mixed material applications.

Why they matter

- Enable consistent, centered force transfer

- Minimize downtime between pile changes

- Reduce material loss and drive errors

- Improve job site safety through stability

Technical Specifications

| Feature | Details |

|---|---|

| Supported Pile Types | Sheet, H-Beam, Pipe, Timber |

| Jaw Material | Hardened Alloy Steel |

| Adjustable Inserts | Yes – interchangeable for different profiles |

| Max Operating Load | Up to 75,000 lbs |

| Clamp Body Material | High-strength structural steel |

| Jaw Swap Time | Under 10 minutes in field conditions |

| Bolt Pattern Compatibility | Fits all Pile Driving USA & major OEM mounts |

| Coating Options | Zinc-coated with marine-grade finish |

| Recommended Inspection | Every 500 hours or monthly |

| Data | UCH25 | UCH50 | USH80 | USH150 |

|---|---|---|---|---|

| Clamping force nominal, tons | 25 | 50 | 80 | 150 |

| Working pressure nominal, psi | 4000 | 4000 | 4000 | 4000 |

| Weight, lbs | 430 | 520 | 1025 | 4300 |

| Length, in. | 26 | 28 | 30 | 52 |

| Height,in. | 22 | 23 | 24 | 42 |

| Width, in | 10 | 12 | 14 | 36 |

Where Universal Clamps Make the Biggest Difference

1. Mixed Pile Projects: Contractors working with both sheet and round piles can use one clamp body with interchangeable inserts — reducing equipment and logistics complexity.

2. Marine & Coastal Construction: Anti-corrosion finishes protect against salt spray, wave exposure, and moisture-driven fatigue.

3. Renewable Energy Sites: Handle large-volume tubular piles in changing soil conditions with precision.

4. Urban Foundation Work: Secure fit prevents pile slippage in confined environments with zero room for error.

5. Infrastructure & DOT Jobs: Meets regulatory standards and accommodates fast pile changes during phased drives.

Field Maintenance & Efficiency

- Jaw inserts are field-replaceable using basic hand tools

- Spare sets can be kept on-site for rapid transitions

- Clamp body lasts across multiple cycles and projects

- Optional quick-change jaw kits available for high-speed operations

Tip: Pre-label jaw sets for specific pile types to reduce errors during changeovers.

What Contractors Are Saying

Built for Speed. Engineered for Strength.

Whether you’re driving 6" pipe or full-size H-beams, Pile Driving USA universal clamps adapt to your pile — not the other way around. Engineered for the realities of job site work, these clamps help you deliver safe, repeatable, and high-performance drives every time.